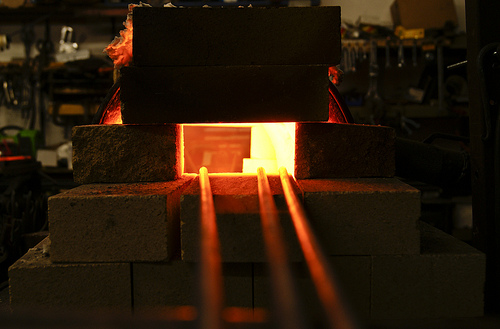

In the production of steel products, steel is molded and reshaped with different machinery at different temperatures. One of the steel manufacturing processes is steel rolling, which involves metal stock passing through a pair of rolls. Rolling produces flat steel sheets of a specific thickness, and the process is classified according to the temperature at which the metal is rolled. If the temperature of the metal is above its recrystallization temperature, or the temperature at which the grain structure of the metal can be altered, then the process is termed as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is termed as cold rolling.

Quite often prior to being rolled, the metal is already hot and above the recrystallization temperature from previous operations. The process removes any induced stresses and grain deformation due to the elevated working temperature. During the cooling process, non-uniformed cooling may occur, which results in residual stress of the product. Hot rolling is used mainly to produce products like sheet metal or simple cross sections, such as rail tracks and I-beams.

Hot rolling is typically not as costly or as expensive as cold rolling or cold drawing, as the steel is more malleable at a higher temperature. There is also one less step when producing the steel, which cuts back on the operating costs of producing the steel. The finish of the steel will not be as smooth or clean as cold rolled or drawn steel, and mechanical properties of the steel are typically not as good as steel in its cold drawn form. This often is not important for steel products that are produced in high quantity and do not need a clean external finish.

Cold Rolled Steel

Cold rolling, done often at room temperature, has the added effect of work hardening and strengthening the material thus further improving the material’s mechanical properties. It also improves the surface finish and holds tighter tolerances. However, room temperature steel is less malleable than hot steel, so cold rolling cannot reduce the thickness of a work piece as much as hot rolling in a single pass. Commonly cold-rolled products often include similar hot rolled products like sheets and bars, but are usually smaller.

Like cold rolling, cold drawing is performed at room temperature, but instead of producing a flat object like a coke can, cold drawing makes steel into the form of a wire like the spokes of a wheel or a paper clip. To start the process, steel is usual hammered and rolled so that it can be fit through a die; a tool that turns the steel mass into a wire. The room temperature steel is pulled through the die which reshapes it into a thinner shape while maintaining the same volume. It is similar to the idea of syrup flowing out of a bottle through a tube in that it changes shape but not volume, but instead of squeezing the metal, it is pulled out. In order to get the wire down to the right diameter, it usually requires more than one pass through different dies.